Using PWM to control a servo

You can use the PWM output, or more technically PPM (Pulse Position Modulation) - to control a servo.

Let’s start with connecting a servo:

We will use port 11, as typically we would use one of PWM-capable pins for servo control, there are alternatives though.

Starting code below:

#include <Arduino.h>

#include <Servo.h>

Servo myservo;

void setup(){

myservo.attach(11);

}

void loop(){

for(uint16_t i = 0; i <= 180 i++){

myservo.write(i);

delay(20);

}

for(uint16_t i = 180; i >= 0 i--){

myservo.write(i);

delay(20);

}

delay(1000);

}

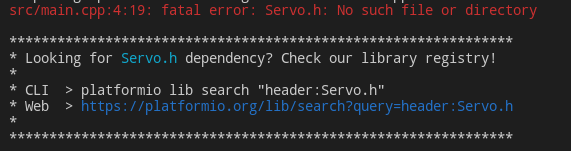

Let’s try to build, and… whoops!

Most likely the code has failed to build due to unavailable libraries:

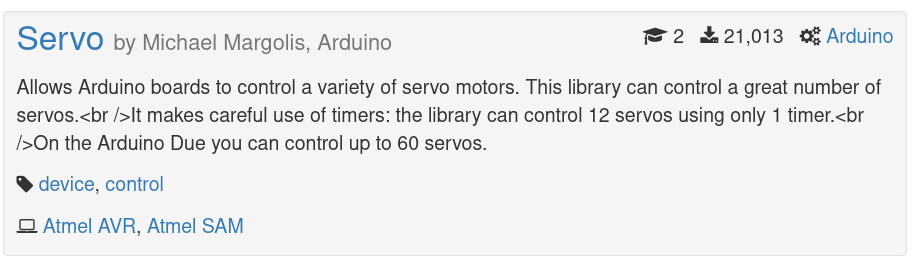

Luckily PlatformIO makes it ieasy for us to solve the issue, let’s try to do what they suggest and use the search on their website: https://platformio.org/lib/search?query=header:Servo.h.

Usually it’s worthy checking out most downloaded libraries first:

If you go to the “Installation” tab you should see the recommended way to add the library as a dependency to your project.

Let’s open up platformio.ini and add it:

Right under framework = arduino let’s paste the following:

lib_deps =

arduino-libraries/Servo @ ^1.1.8

Let’s try again to build, upload and verify. Now the servo should be moving from 0 to 180 degress and then down from 180 to 0.

TASK: Servo action after a button press

Let’s try to build a simple logic with the servo that will:

- set up an interrupt for a button press

- move the servo quickly to 100 degrees

- hold for 3 seconds

- move the servo slowly to 140 degrees

- hold for 1 second

- move the servo quickly back to 0 degrees The imagined use case is that you are opening something up based on a button press.

Suggestions:

- if you just set the servo to given angle it’s reaction could be too dynamic, let’s try to use loops to make the movement with a manageable speed.

- rather than using three separate loops, you could write a single function that would move the servo from given angle to given angle, with a specific speed,

Using digital gpio to control a stepper motor

It is also possible to use plain digital GPIO to control a stepper motor via an external driver.

Please connect the stepper motor driver to the Arduino:

IN1- GPIO11IN2- GPIO10IN3- GPIO9IN4- GPIO85V-5VGND-GND

And let’s try the starting code:

#include <Arduino.h>

#include <Stepper.h>

const int stepsPerRev = 200;

Stepper myStepper(stepsPerRev, 8, 9, 10, 11);

void setup(){

myStepper.setSpeed(50);

}

void loop(){

myStepper.step(stepsPerRev / 100);

}

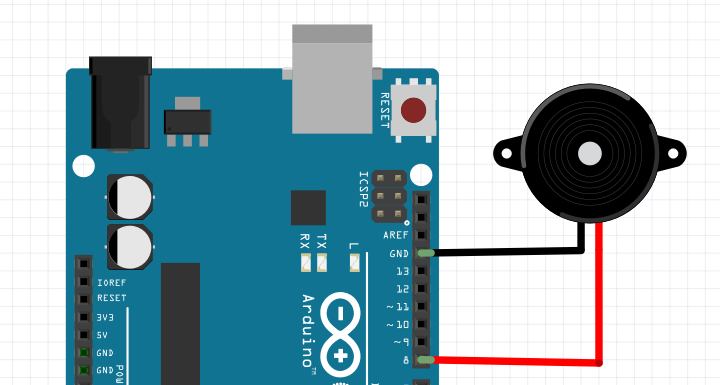

Using PWM to control a buzzer

PWM can also be used to generate simple, square wave tones and emit sounds with a buzzer.

You can just connect it to any of the PWM capable pins and ground:

Starting code would be as simple as this:

#include <Arduino.h>

#define BUZZER_PIN 9

void setup(){

pinMode(BUZZER_PIN, OUTPUT);

}

void loop(){

tone(BUZZER_PIN, 440, 100);

delay(1000);

}

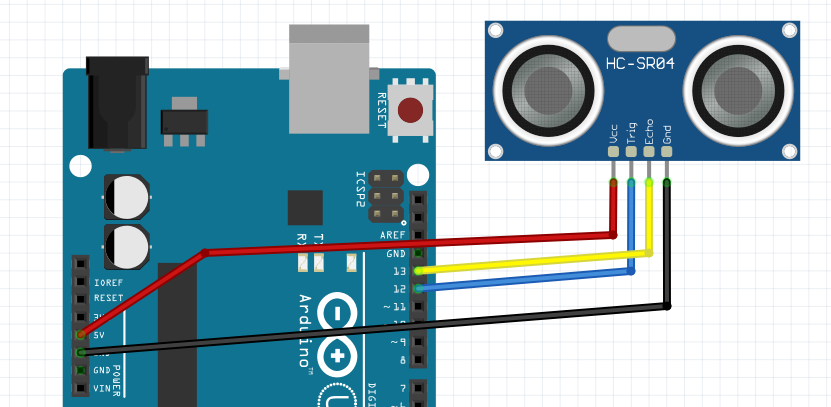

Ultrasonic distance measurement

Let’s try to use an ultrasonic distance measurement module. It works on a simple principle of sending and ultrasound signal and waiting for it to bounce back.

To connect it to your board you need to attach power (5V & GND) and two digital signals - TRIG and ECHO. Any digital pins can be used.

Example wiring on a diagram:

To work with the sensor you will need a proper library. A quick search on platformio would bring up: https://platformio.org/lib/show/1507/Ultrasonic

Let’s try to add that library to your project (edit platformio.ini) and try a basic example.

#include <Arduino.h>

#include <Ultrasonic.h>

Ultrasonic ultrasonic(12, 13);

void setup() {

Serial.begin(9600);

ultrasonic.setTimeout(40000UL);

}

void loop() {

Serial.print("Distance [cm]: ");

Serial.println(ultrasonic.read());

delay(1000);

}

Let’s try to build, upload & verify the serial output.

TASK: Lowering the sensor timeout for robustness

Important note - observe what happens when there is nothing in front of the sensor - how long it takes for the code to timeout practically blocking the code from moving with any other work.

If you have an use-case that doesn’t really require full sensor range (typically up to 200cm), but you only care if there is something close to the sensor - you can address that issue setting the timeout lower.

Let’s try to modify

TASK: build a complete parking sensor solution

Now you should have all the tools required to build a fully functional parking sensor.

Let’s try to implement the following:

- ultrasonic sensor with distance measurement in the range of 0-50cm

- a few LEDs displaying the measured distance

- buzzer that will change its tone and period between beeps when the object gets closer

Next steps

Now let’s continue to work with digital I2C bus and an OLED screen